In the challenging environments of Western Australia, transportable buildings are increasingly prevalent. Our site buildings are manufactured in compliance with the National Construction Code and Energy Efficiency requirements. They are specifically designed to meet the distinct challenges of both cyclonic areas—particularly the demanding Cyclonic Region D2—and non-cyclonic regions.

Table of Contents

This blog will explore the essential differences in design and construction standards between cyclonic and non-cyclonic transportable buildings. It aims to provide key insights for those looking to make informed decisions about their building needs in varying environmental conditions.

Understanding Cyclonic and Non-Cyclonic Transportable Building Regions in Australia

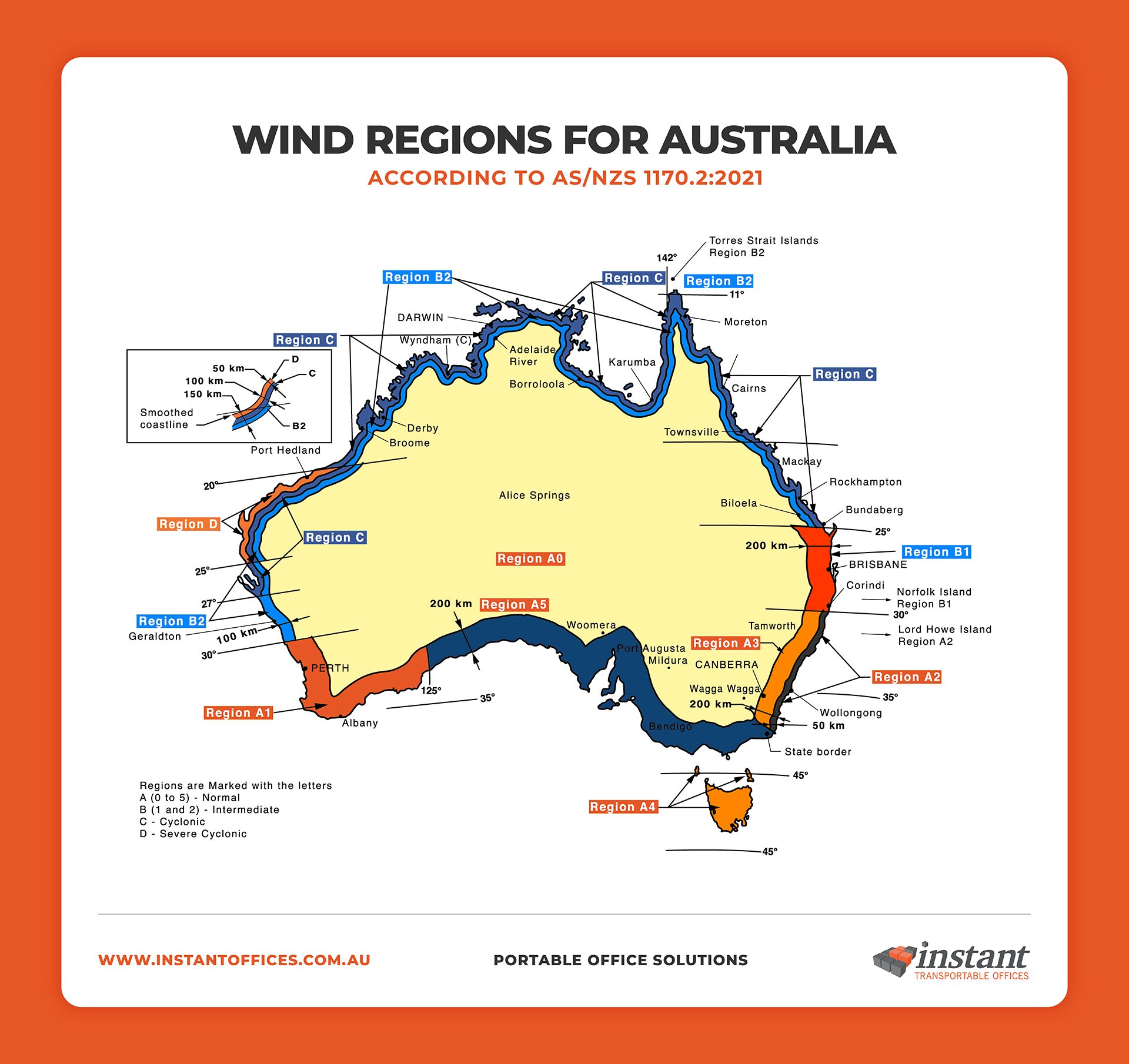

AS/NZS 1170.2:2021, a standard for structural design actions related to wind actions, classifies regions in Australia based on wind speeds. This classification significantly impacts building requirements as outlined in the Building Codes of Australia (BCA). The regions are divided as follows:

- Region A: Known as the ‘Normal’ region, with wind speeds up to 162 km/h.

- Region B: Termed the ‘Intermediate’ region, experiencing wind speeds up to 205 km/h.

- Region C: The ‘Cyclonic’ region, where wind speeds can reach up to 238 km/h.

- Region D: The ‘Severe Cyclonic’ region, facing the highest wind speeds of up to 288 km/h.

These categorisations are crucial for ensuring that construction standards are appropriately tailored to withstand the specific environmental challenges in each region, particularly regarding safety and structural integrity. See below for a visual guide on the regions.

Structural Requirements for Cyclonic Transportable Buildings

Transportable buildings in cyclonic regions require enhanced structural features for resilience against high winds. Key aspects include:

- Reinforced Materials & Construction: Cyclonic areas demand robust materials such as steel and reinforced concrete. These materials are chosen for their strength and resistance to the intense forces of high winds.

- Enhanced Anchoring Systems: A crucial aspect of cyclonic buildings is their anchoring. Properly designed and implemented anchoring systems are essential to secure buildings to the ground, preventing them from being dislodged during high winds.

- Wind Resistant Design: The design of these buildings assumes potential breaches by debris during a cyclone, leading to high internal pressures. This necessitates stronger fittings, especially connecting the roof to the main structure, to prevent catastrophic failures.

Crucially, a structural engineer is involved during our design process to ensure compliance with all relevant codes and standards, particularly in cyclonic areas. Through our 21 years of manufacturing buildings we have a library of standard cyclonic tie down and footing arrangements designed in consultation with our structural engineer. We can supply footings and tie downs ex-Perth with your project. We hold in stock our standard components even for cyclonic areas.

In non-cyclonic areas, the construction standards are less stringent, reflecting the lower risk of extreme wind conditions. This differentiation highlights the importance of region-specific designs for safety and longevity of structures in diverse environmental conditions.

Positioning and Concrete Footing of Buildings

In cyclonic areas, the positioning and footing of transportable buildings require specialised design. Elevated footings, strategic orientation to counter prevailing winds, and customised footing and tie-down details by a structural engineer are essential. This design takes into account the specific site location and building orientation for maximum safety against cyclonic conditions.

Conversely, in non-cyclonic regions, the focus is more on accessibility and location suitability, with less stringent requirements for wind resistance. Comprehensive site assessments are crucial in all regions to ensure safety, compliance, and structural resilience.

Leave it to the Experts: Ensuring Compliance in Cyclonic Conditions

In Western Australia, the distinctions between cyclonic and non-cyclonic transportable buildings are crucial for project management. Cyclonic buildings require enhanced structural resilience and specific design considerations compared to their non-cyclonic counterparts. Understanding these differences is key to ensuring safety and compliance.

Explore our range of cyclonic and non-cyclonic dongas in Perth to find your perfect solution. At Instant Transportable Offices, we handle all the complexities that come with cyclonic buildings, from manufacturing to installation, ensuring a seamless process. Call us at 1300 556 241 for an instant solution tailored to your needs.

For more information on cyclonic ratings for buildings, please refer to our General Specification Brochure.

For those seeking durable and compliant demountable buildings, Instant Transportable Offices is your go-to provider. Whether you’re looking for a demountable building for sale or need a custom solution, our team at 18 Rogers Way, Landsdale WA 6065, is ready to assist. Contact us at +61 (0) 8 9406-6600 or for 24/7 customer support, call 1300 556 241.

Frequently Asked Questions

What is the main difference between cyclonic and non-cyclonic transportable buildings?

Cyclonic transportable buildings are engineered to withstand higher wind speeds and feature reinforced materials, advanced anchoring systems, and wind-resistant designs. Non-cyclonic buildings are designed for areas with lower wind speeds, prioritising accessibility and suitability for specific locations.

Why are anchoring systems crucial for cyclonic transportable buildings?

In cyclonic regions, anchoring systems are essential to firmly secure buildings to the ground, preventing them from being uplifted or damaged during high winds. These systems are specifically engineered to handle the intense forces of cyclones, safeguarding the structure’s integrity and ensuring safety.

How do construction standards differ between cyclonic and non-cyclonic areas?

Construction standards in cyclonic areas demand more rigorous specifications, including the use of stronger materials and specialised design features to resist high winds and debris impacts. In contrast, standards in non-cyclonic areas focus more on general safety and environmental suitability, with less emphasis on wind resistance.

Can Instant Transportable Offices provide buildings for both cyclonic and non-cyclonic regions?

Yes, Instant Transportable Offices supplies a variety of transportable buildings suitable for both cyclonic and non-cyclonic conditions. With over 21 years of experience, they ensure that all buildings comply with the necessary codes and standards, offering safe and reliable solutions tailored to diverse requirements.

Managing Director at Instant Transportable Offices

Scott Rawson is the Managing Director of Instant Products Group, a specialist group of companies that offer portable building solutions, including sea containers, transportable offices, and portable sanitation products. With more than 20 years of experience in various management positions and a finalist in the WA Business News 40 under 40 awards in 2013, Scott is a highly motivated entrepreneur that has a passion for designing products to suit the needs of individual markets. From the creation of Instant Products Group over 20 years ago, he has successfully grown the group into a multi-million dollar corporation and his success is widely recognised in Western Australia. Scott is dedicated to expanding Instant Products Group nationally and providing high-quality products to a range of sectors, including mining, engineering, property development, and government.